Rapid development of the electronics and manufacturing sectors, along with rising environmental concerns, are driving up demand for passive infrared sensors

Any object that exceeds the temperature of absolute zero emits heat in the infrared part of the electromagnetic spectrum outside the range of human sight. That makes PIR electronic sensors – also referred to as passive infrared, pyroelectric or IR motion sensors – a potent means of detection.

These sensors can lock on to an infrared-emitting source, rendering this a formidable technology across a seemingly limitless range of applications, such as security devices, automatic lighting, security alarms, thermal cameras, spectrometers, gas and fire detection systems, pyrometers and temperature sensors. Similarly, it has a proven track record as an ally on the battlefield.

“Pyroelectric and thermopile-based technology can sense heat without contact. This has the ability to absorb even very weak infrared waves from its surroundings. Pyroelectric sensors react to temperature changes. Thermopile-based sensors, on the other hand, can measure absolute temperature in certain fields of view (FOV),” Safija Palme, field application engineer for sensor technology at Arrow Electronics.

A need to improve power efficiency in applications such as server rooms, for example, has placed a new focus on temperature management. Thermal pictures are now a basis for the algorithms optimising ventilation and cooling systems in these facilities. “The higher power consumption and heat dissipation is, the greater the danger of developing hot spots that could damage a system or even cause it to combust,” says Palme. “Remote measurement of such high temperatures protects conventional measuring systems from potentially dangerous exposure, and makes the solution safer and simpler.”

DETECTION AND PROTECTION

Applications also include single contactless fever sensors for medical purposes and multipixel temperature monitors that can scan temperatures in large rooms. “The latter allow a temperature map to be displayed, showing a particular FOV that can be interpreted as a thermal picture. This can be used to detect the position of a person in a room, while protecting their anonymity. There are many applications in the health sector using this technology to establish smart patient care services,” she adds.

According to Future Market Insights (FMI), the widening application area of passive infrared sensors is rapidly accelerating commercial success: “Expanding demand for motion-enabled smartphones, industrial machinery, medical equipment, and military and aerospace devices, as well as the rising uptake of wireless communication, and growing trends of industrial as well as home automation, are all contributing to that growth,” the research company states. In industrial fields, PIRs are also used on assembly lines to keep track of the number of products and shut down dangerous equipment, should someone get too close.

All the more reason, says Martin Keenan, technical director at Avnet Abacus, to pick the right kind of PIR sensor for the task in hand. “The various offerings on the market use the same core architecture, but there are increasingly important differences in design and construction. The IR radiation typically enters the sensor housing through one or more windows at the front and lands on a set of panels made from a pyroelectric material – one that generates an electric current when exposed to IR energy. The pyroelectric materials vary from inorganic gallium nitride and caesium nitrate, to carbon-based polyvinyl fluorides and phenylpyridines.”

HOW IT WORKS

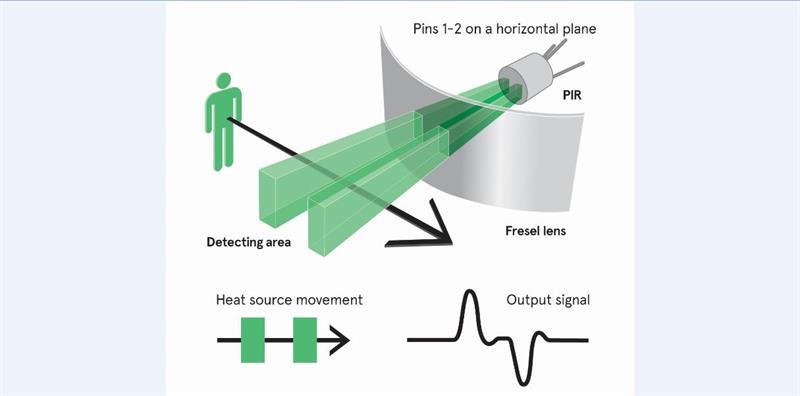

In a typical PIR motion sensor, there are two rectangular windows that allow IR to penetrate. “Behind each window is a sensor with electrodes attached in such a way that one sensor provides a positive output signal and the other a negative output signal. If no object is detected, both sensors receive the same amount of infrared radiation and their signals cancel out. But if a warm body passes into the view of one of the detection sources, its value deviates from its paired sensor, causing the sensor electronics to register change in output,” he adds.

A Fresnel lens (a type of composite compact lens) in front of the window area can be used to increase the sensing range of the sensor, and detection angles and detection patterns to be matched to the requirements of the respective application. “Various sensor layouts, many of which use more than two pyroelectric elements arranged in a grid, provide the ability to tune performance for different applications,” he points out. “For instance, the lens and array configuration in Panasonic’s AMN series is optimised to detect motion within a narrow field of view, suiting the product to vending machine and light switch applications, compared to the general-purpose EKMB and EKMC series.”

To improve usability, the PIR sensor will often include an amplifier – Keenan offers the IRA-S210ST01 from Murata as one example, with this three-port device incorporating a low-noise junction field effect transistor that converts the electrode outputs to a convenient output level. “Manufacturers will generally offer a choice between logic and analogue outputs. In general, the analogue output will offer more design flexibility and provide the ability to apply filtering circuits or components to improve performance under noisy conditions. Logic outputs provide an easier design path for simpler applications,” he advises.

While the applications for this smart connected technology are many and varied, some of the most established and common are in the area of building energy management (BEM). With energy costs rising and environmental consideration high on almost every agenda these days, making good use of energy is an increasingly important topic. “Along with the ability to manage efficient use of energy, most smart building systems provide a high level of automation, which delivers convenience to building occupants,” says Alessandro Mastellari, technical specialist at Avnet Abacus. “However, to be truly useful, these systems need the ability to detect the presence [or absence] of humans. With this ability, they can deliver automated ‘on demand’ energy management, turning lights on and controlling the environment when it is needed.”

ULTRASONIC OPTIONS

An alternative approach to PIR is to use ultrasonic transducers. “This uses sound waves at a frequency higher than humans are able to hear – typically in the range 30kHz to 10MHz,” Mastellari points out. Both PIR and ultrasonic detection can be used in standalone systems and ‘connected’ (IoT) systems, principally to detect the presence of humans. However, PIR sensors do require the person to be moving, whereas ultrasonic sensors can scan a room and know when one or more people are present, even when stationary.

According to Avnet Abacus, ultrasonic transducers comprise of a transmitter and a receiver. A sound pulse is sent out at a given frequency and, as it bounces off objects in its path, it is reflected and captured by the receiver. In an empty room, the reflections will come from the opposite wall, but when a human enters the pulses will reflect from them and, as they are closer than the wall, the time taken to receive the reflections will be less. The sound waves travel at a constant speed – meaning that the object distance can be detected by knowing the time taken for the sound pulse to be received.

As part of a more sophisticated BEM, this information can be used to control and automate heating, ventilation and air conditioning (HVAC) systems to save energy and minimise environmental impact.

Clearly, this technology is making rapid in-roads, but there are barriers as well. Future Market Insights points to a number of restraints it believes are hindering further global growth, such as “the availability of alternative sensors at lower price, along with the inability of passive infrared sensor to detect objects moving at very slow speed”. The expectation, though, is that these challenges will be resolved in the not too distant future, especially with so much to be gained.

By Brian Wall